Troubleshooting in Automotive Electrics

One of the most common faults to be treated in automotive workshops today is the so-called voltage drop. If a voltage drop test is not performed, countless unexplained electrical faults remain, especially if they affect the ground side of a circuit. This can also lead to parts being replaced that are not faulty at all.

The more connections and wiring there are in a vehicle, the more susceptible the electrical system is to a voltage drop.

In order to avoid a voltage drop, it is recommended to handle electricity safely. This involves measuring voltage drop before drawing any conclusions. A "voltage drop" in a circuit means that it is too limited to operate or operate correctly on a component (motor, relay, incandescent lamp, etc.). Confined circuits shall be repaired and retested. If there is no longer any limitation, but the component still does not run (correctly), replace it.

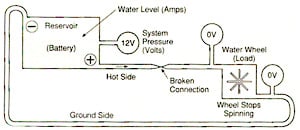

In this example, if the water pipe fails completely, water will no longer flow, the pressure will drop to zero and the water wheel will no longer turn. In the electrical field, the same happens when a cable drops or a connection is lost. The current stops flowing and the voltage drops to zero. A starter would no longer run or a headlight would go out.

Signs of a voltage drop

Signs of electrical voltage drops can vary depending on the function of the circuit or the severity of the voltage drop. This can be confusing and contradictory.

- Non-operational electrical parts

- Sluggish and low-drive electrical devices

- Irregular and intermittent devices

- Equipment that is delayed or malfunctioning during periods of high electrical stress

- Excessive radio interference or noise in the radio

- Damaged throttle cable or transmission cables or connections

- Repeated failures of throttle cable or transmission cables

- Damaged powertrain parts

- Engine or transmission performance issues

- No start or starting difficulties

- High sensor or computer voltages

- Faulty engine or transmission computer performance

- Incorrect error codes in the memory of any on-board computer

- Premature or repeated clutch failure on the AC compressor

This list of symptoms reveals a number of aspects.

- Most electrical voltage drops cannot be detected by visual inspection. The corrosion in a connection or the damaged cable that is causing the problem is usually not visible.

- Voltage drops on the earth side can be the cause of most of these symptoms and are often overlooked. An electrical circuit or component is only as good as the associated grounding.

- The more complicated the electrical system, the more important the grounding is. The number of electrical components has increased rapidly, and most do not have separate ground wires. Instead, the devices are grounded to the engine or body. Rust, grease, vibration and/or careless repairs can restrict the circuit from the engine/body to the battery and back.

- Many components such as motor sensors are connected to the same earth. Faulty grounding therefore makes diagnosis more difficult because it affects several components at the same time.

- In some workshop manuals and diagnostic diagrams or fault tree structures, it is recommended to do the inspection of the earth last. In reality, it is much faster if you first check the ground connection and then go through the fault tree structure.

- It is faster and more sensible to routinely check the voltage drop of an electrical circuit than to memorize long lists of symptoms. If experience has taught us one thing, it is that the elaborate symptom analysis cannot be a substitute for a routine and thorough stress drop analysis.

Through our experience, we know other reasons why the voltage drop should be checked first. Voltage drops, which usually occur on the Earth's side, cause inaccurate or strange voltmeter readings and oscilloscope patterns. In addition, if you connect a voltmeter or oscilloscope to a system with faulty grounding, the test meters themselves can provide a good replacement grounding. This can be frustrating because the circuit works as long as the devices are connected, and then you won't find a fault!

Basic Procedures

Whenever you are dealing with an electrical problem, you should take it easy and consider the most basic electrical component, series connection. Drawings 1 to 7 show basic series connections. No matter how complicated a system may be, you can always reduce it to mini-series circuits. Then check each circuit for a voltage drop.

Compare electricity to water flowing through a water cycle. Due to the water pressure inside the tank, water is transported through the pipe by the litre. The water drives the water wheel and then flows back into the reservoir. In an electrical circuit, the electrical voltage (voltage/volt) drives the electrical volume (current or ampere) through the circuit, driving a load in the process. This load can be a computer, a motor, a lamp, a relay or any other device. In the water cycle, the water consumes most of its energy to drive the water wheel. The water continues to flow to the reservoir, but at a lower pressure.

Similarly, the electrical pressure (voltage) is consumed during the operation of the load. Accordingly, the voltage on the earth side drops to about zero while the current continues to flow to the battery. Since the voltage in an intact ground connection should be about zero, some technicians call it ground zero.

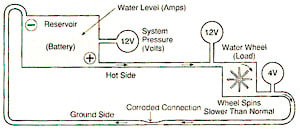

A kinked return water pipe to the reservoir slows down the water wheel and provides a pressure reading on the back of the wheel. In the same way, a voltage drop reduces the load power and creates a voltage value on the ground side of the load.

Resistance – Restriction

To illustrate excessive resistance, imagine a kink that limits the flow of water through a pipe. A kink in a water circuit (whether on the supply or return side) obviously leads to a limited water flow, so that the water wheel slows down or no longer rotates at all.

Excessive resistance affects an electrical circuit in the same way. Faulty connections and damaged or too small cables behave like a pipe with a kink and limit the flow of electricity. As with the water cycle, limiting the flow of electricity at any point – whether on the hot side or the ground side – reduces the power of the load. The effect of the load is difficult to predict because it varies depending on the extent of the limitation. For example, the motor can fail completely in a limited circuit or just run slower than usual.

A limited circuit can cause an A/C compressor clutch to slip and burn out prematurely. A computer that is connected to a limited circuit can shut down or become error-prone. Corrosion, loose terminals, or other types of resistance limit the circuit and lead to a drop in voltages and amps. As the voltage drops, the amperage also decreases. So if you find a voltage drop on a connector or cable, you know that the connection or cable is limited.

Take a look at the water cycles in our drawings and remember two essential points. A free flow on the earth side is just as important as on the live side. Voltage values above 0–0.1 V in an earthing connection can only be caused by a restriction on the ground side.

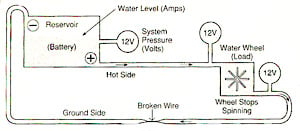

A completely failed return water pipe brings the water wheel to a stop and a pressure reading is created on the return side of the wheel. In the same way, the current flow is completely blocked by a damaged ground wire, the load is switched off and a system voltage is created on the ground side of the load.

Voltage drop tests

The amount of voltage drop varies depending on the current flow. As long as the circuit is operated in such a way that current flows through it, no voltage drop is measurable. Because an ohmmeter's battery can't produce the voltage that flows through most circuits, ohmmeter testing can't detect limitations as accurately as voltage drop testing.

Open circuits, such as those caused by damaged or disconnected cables or cable connections, bring the current flow to a halt. After you have closed the circuit again, turn it back on and check if the voltage drop is still present. Only when the current is flowing again and you have checked the circuit again can you say with certainty whether the overall circuit is working again.

Resistance-free connectors, wires, and cables would be ideal, but most of them provide at least some voltage drop. If your manuals do not list voltage drop values, use the following limits:

- 0,00 V an einer Verbindung

- 0,20 V an einem Draht oder Kabel

- 0,30 V an einem Schalter

- 0,10 V an einer Erde

Da die meisten Computerstromkreise nur im unteren Milliamperebereich betrieben werden, ist die Toleranz für Spannungsabfälle dort geringer als in anderen Schaltkreisen. Beachten Sie: Ein Milliampere entspricht einem Tausendstel (0,001) Ampere. Der empfohlene maximale Abfall zum Arbeiten entspricht 0,10 V bei Niederspannungskabeln und -schaltern. Zum Testen von Niederspannungsstromkreisen ist auch ein Voltmeter mit einer hohen Impedanz (10 Megaohm) erforderlich. Ein Voltmeter mit geringer Impedanz könnte so viel Niederspannung messen, dass es einen falschen oder gar keinen Messwert ausgibt. Die meisten professionellen Digitalmultimeter (DMMs) verfügen über eine Eingangsimpedanz von 10 Megaohm. DMMs bieten die schnellste Möglichkeit zur Messung von Spannungsabfällen. Wenn Ihr DMM über keine automatische Bereichswahl verfügt, verwenden Sie für den Spannungsabfalltest eine Niederspannungsskala (0–1 V). Denken Sie daran, dass Testleuchten zur Diagnose elektrischer Spannungsabfälle nicht genau genug sind.

If there is an excessive voltage drop, repair the grounding connection of the motor and then repeat the test. Note that on some distributorless ignition systems, the easiest way to prevent an engine from starting is to pull the fuel pump fuse. Then connect the digital multimeter between the negative battery terminal and the vehicle's bulkhead, then start the engine and the main electrical accessories. Is the voltage drop too high? Then check the body grounding and run the test again.

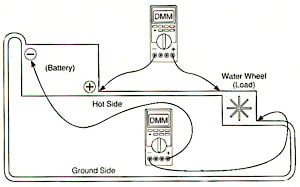

Once the values of the engine and body earthing are within the limits, you can proceed with the diagnosis. If the problems on the vehicle can be solved by troubleshooting these earths, this is nothing out of the ordinary. If a vehicle passes the body grounding test, it doesn't mean you can ground the voltmeter anywhere you want. Some technicians have been going around in circles for hours because their voltmeters were not well grounded. For safe handling of electricity, you should cut a jumper wire of approx. 6 or 9 m length with alligator clips at both ends. If you need to test an electric fuel pump, lighting system, or ABS computer at the back of the vehicle, ground the digital multimeter to the battery with the jumper wire.

Computer Grounding Kinks

Because computer circuits operate at such low current, very low grounding cannot necessarily be determined with the standard grounding tests on an on-board computer. Before you decide on the cause on the on-board computer, first check the associated grounding. Turn on the computer system and first check each computer ground connection. If you're measuring anything above 0.10V, trace that ground connection to pinpoint the problem.

Sometimes computer grounding systems are connected to a place where malfunctions or corrosion can easily occur, such as a thermostat housing bolt. The terminals of computer connectors can also corrode. Sometimes it is enough to remove the connector and spray the terminals with electric cleaner to fix the voltage drop.

Experience has shown that as little as 0.30 V on a computer grounding connection can cause problems. Try to determine this for sure with a test light! Faulty computer and/or sensor grounding can lead to increased sensor voltages and incorrect error codes. In many cases, the faulty grounding prevents the sensor or computer from detecting a voltage signal at or near zero. Of course, accessing the computer to test the grounding is not necessarily convenient. However, accidentally replacing expensive sensors and computers is a bigger evil.

Connect a digital multimeter to a section of the circuit. The voltage drop on wire, cable, switch or connection is read out directly. Here, a digital multimeter would indicate the voltage loss between the battery and the load. The other would indicate the voltage loss from the ground side of the load to the battery.

Keep your eyes open when grounding the body

Always pay attention to missing body grounds. Maybe someone else was working on the vehicle and then forgot to reconnect the grounding wires of the body. Bear in mind that with limited body grounding, the current has the ambition to get back to the battery by other routes. The easiest alternative route could be through the gearbox shift cable or the throttle cable cable. This current can not only weld the cable together, but also seize or erode the sockets and bearings in the gearbox.

If you find that the insulation on the body ground wire is burnt or has bubbles, it is most likely that the cable has been overheated by the inrush current. When motor grounding is limited, the inrush current strives to return to the battery via the body's grounding connection. Experience has shown that the customer usually does not even notice the problem immediately if the body-grounding connection can absorb the current load.

In the event of high current flow, restricted body grounding can impair or shut down components in operation. As is well known, turn signals can stop flashing when the brake pedal is pressed. Tests confirmed that the flashing signals were suppressed by limited body grounding. The current of the flashing signals and brake lights could not be processed simultaneously via the earth.

Secure service

By using electricity safely, you can solve electrical problems faster and more profitably than guessing and replacing parts. Start your digital multimeter today by turning off electrical voltage drops. This is how you show responsibility.